Short Circuit Current Ratings for UL 508A Industrial Control Panels

NEC Requirements for Short Circuit Current Ratings (SCCR)

Equipment short circuit current rating and overcurrent protective device interrupt rating are two important safety considerations for electrical systems which can cause a serious potential safety hazard if not designed adequately.

Due to the seriousness of this issue, NEC has added requirements that have to be considered during the design of equipment and its specifications. These requirements can be found in 2020 NEC Article 110.9 and 409.22.

If a violation of code occurs, and the fault current exceeds the interrupt rating of the overcurrent protective device or the SCCR of the equipment can result in a catastrophic, explosion of the overcurrent protective device or equipment which is a serious fire and shock hazard. Therefore, this topic also finds importance from the Occupational Safety and Health Administration (OSHA) containing similar language to NEC.

Definitions

Prospective Symmetrical Fault Current or available fault current is the average current available on the line side of equipment with the line in shorted condition.

Short Circuit Current Rating (SCCR) is the prospective symmetrical fault current at a nominal voltage to which an apparatus or system can be connected without sustaining damage exceeding the defined acceptance criteria. (Ref. UL 508A, par 2.44).

Interrupt Rating (IR) is defined as the capacity of a protective device to maintain its integrity when reacting to fault current. IR of the overcurrent device must be no less than the current available at the equipment's line terminals.

SCCR should not be confused with IR as both are not the same.

High Fault SCCR is the marked SCCR of a component that is greater than the standard fault short circuit current rating.

Importance of SCCR and associated consequences when equipment SCCR is inadequate

Typically, the acceptance level of damage can render the component useless. The main purpose of the product standard SCCR acceptable damage level is to prevent shock hazard or a fire outside of the enclosure. SCCR on equipment labels must be no less than the available fault current where the equipment connects to the system which means that the industrial control panel must be manufactured with an SCCR rating that is adequately designed for installation.

The system designers and installers have realized over a period that if the equipment is installed with inadequate SCCR then the corrections required and mandated by AHJs are not easy to fix and would require equipment modification and recertification or reduction of fault current. Further, if the equipment might be relocated within the facility or between plants concerns arise on the flexibility of the application of the equipment. To prevent such delays cost overruns and equipment relocation possibilities, equipment suppliers are being requested to provide equipment with higher SCCR, which also helps to meet the requirement of the NEC. This in turn results in an equipment design change to meet the requirement of high fault current installations.

Calculate SCCR for control panels

For components and assembly components, the SCCR is typically determined by product testing. The testing station is calibrated to have the prospective symmetrical fault current available at the test station terminals. The short circuit current is supplied through the shorting bus bar. The component or assembly is connected to the test station with conductors sized based on the rating of the component.

Should the device or assembly have no overcurrent protective device included, then a separate overcurrent protection device is added to the circuit. The load side connections are shorted together. The actual current that flows during the short circuit test is less than the prospective symmetrical fault current. Based on acceptable test results, the component is marked with short circuit current and voltage rating.

The test is conducted by the product connected to the test station terminal with up to 8ft of field wiring, overcurrent protection, and shorting bar being removed. The resulting current flow is less than the SCCR. The test results are defined in UL508A component standards. The results obtained may vary depending on the intended use of the component.

For example, if the component is an overcurrent protection device then it must interrupt the fault current, maintain calibration, and if the component has a resettable feature the component must be able to reset after the test is completed. Similarly, for a disconnect switch under test, the contacts cannot weld and shall be operable after the test. However, for all other devices, no opening of enclosures, no wire pullout of terminals, and no cracking or breaking of insulating bases are allowed.

For assemblies, the marking can be determined through the equipment product listing standard or by an approved method. An industry-accepted procedure for UL508A, UL Standard for Safety for Industrial Control Panels, is available since 2005 NEC. The UL 508A, Supplement SB provides an analytical step by step procedure to determine the SCCR of an industrial control panel. It requires a careful selection of panel devices with adequate SCCR.

This procedure is based upon the weakest link approach where the installed device with the lowest SCCR will dictate the overall SCCR of the entire panel. In other words, the assembly marked short-circuit current rating is limited to the lowest-rated component short circuit current rating or the lowest rated overcurrent protective device interrupting rating.

Increase SCCR of an industrial control panel

There may be a need to increase the SCCR of industrial control panels to meet onsite install conditions or to meet the requirements of an established standard and regulation. There are several ways to do so which include the use of components or approved combinations with higher SCCR. Protection with current-limiting fuses and current limiting components in the feeder circuit can help to increase SCCR. Similarly use of overcurrent protective device with higher IR in branch and control circuits. Use of current-limiting fuses is the easiest, lowest cost, and most effective way to achieve higher short-circuit current ratings.

SCCR marking requirements

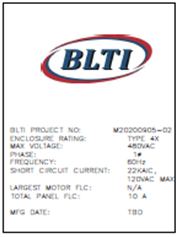

The 2005 NEC added SCCR marking requirements for industrial control panels in 409.110, see figure. The nameplate rating of an industrial control panel shall include: "Short Circuit Current Rating: ___kA RMS symmetrical, ___V maximum". (Ref. UL 508A, par SB 5.1).

If the branch circuit protection device or the feeder circuit protection device is not provided with an industrial control panel marked with high fault SCCR then it is required that the panel is marked with the information about the type and size of branch circuit protection and feeder circuit protection required to be installed in the field.

Later in 2008 NEC, 409.110 was modified to add an exception that SCCR is not required to be marked on an industrial control panel that contains only control components.

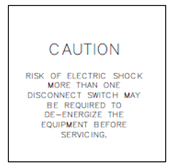

An industrial control panel with SCCR based on high fault SCCR of one or more components shall be marked with cautionary labels. (Ref. UL 508A, par SB 5.2).

Conclusion

The panel designer should follow the procedure set up by the UL 508A standard to determine and calculate the SCCR of their manufactured products. It is the panel designers' interest to understand the required level of short circuit protection that would be required by the end-user who will own, operate, and maintain the manufactured control panel. It is also a business decision for the industrial control panel shop to agree with the panel design and manufacture industrial control panels for a certain SCCR rating as achieving a higher SCCR may also increase the cost of the control panel, which will affect both the manufacturer and the end-user. The short circuit current rating provides a key piece of information in ensuring the appropriate level of protection and assurance to the manufacturer and end-user, that their systems are in adherence with national and local installation codes and standards, are highly reliable, and are safe for workers to use and maintain.

References

[1] UL 508A, Third Edition, Standard for Industrial Control Panels

Disclaimer

The information provided in this white paper is intended solely for general information purposes and that the author and publisher are not herein engaged in rendering engineering or other professional advice or services. Any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. We do not accept liability for direct or indirect losses resulting from using, relying, or acting upon information in this white paper.By accepting you will be accessing a service provided by a third-party external to https://blti.com/